EFC comfort technology is changing the way we all think about comfort!

The issue of comfort has been a concern to mankind since the beginning, yet the first significant solution only appeared in the courtyards of kings in the 16th century, when cotton, linen and hair coated with fabric, and then feather cushions were placed on the seating and lying furniture.

Travel with EFC on the train of comfort history and be among the first to cross into the platform of the future with us.

1826

Thanks to Pratt’s patents, he became the biggest importer for King George IV. and British upholsterers.

![]()

Henrich Westpal creates the bonnell spring mattress in Germany by stitching double cone springs

1871

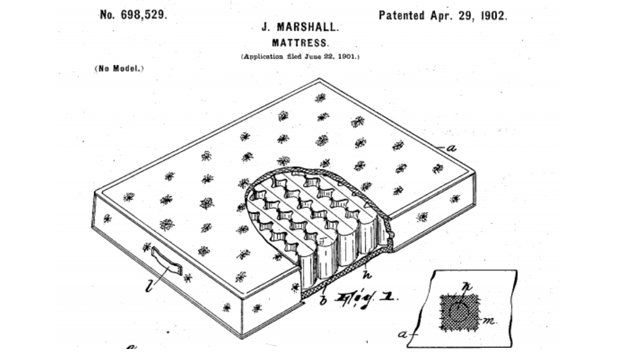

1902

![]()

James Marshall created the marshal, or sack spring, which was also found in the sleeping quarters of the Titanic and the Queen Mary. Founded by ViSpring, the British company now exports luxury mattresses to more than 14 countries and has the Queen’s Award for Enterprise for the most innovative businesses.

Westpal’s invention was ahead of its time, and the mattress structure in hospital beds gradually replaced the straw and other stuffed hard bed sponges. However, the Marshall spring reformed the concept of beds. It has made it a symbol of luxury and everyday comfort. The popularity of the Marshall spring has been unbroken for a century and a half and is the foundation for the development of beds and mattresses.

The French mattress manufacturer Epeda introduced the Epeda spring system, which was made of continuous steel wire and was more durable than its ancestor, the bonnell spring.

The 90-year-old Epeda company is a fairy tale story of French success. They are still France’s leading mattress manufacturer, with a reseller network of nearly 2,500 stores.

1929

1929

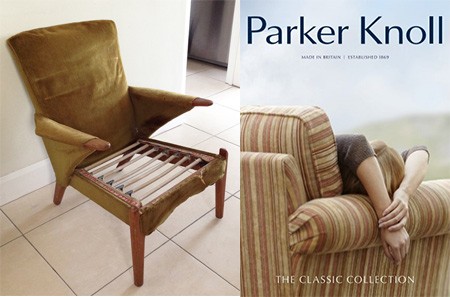

Peter Knoll, the English master of chairs and couches, created the tension spring, thus triggering the innovation wave of chair cushions.

Founded more than 150 years ago, the British brand Parker Knoll is now synonymous with high-quality, luxurious, handmade chairs and sofas. It is one of the brands that makes a regular appearance in auction houses.

The competitor to the spring mattresses is the foam mattress, which was made of natural Latex materials developed by the Swiss company Dunlop in 1920.

The first manufacturer of latex mattresses, Dunlopillo, is still the leading manufacturer of latex mattresses.

1934

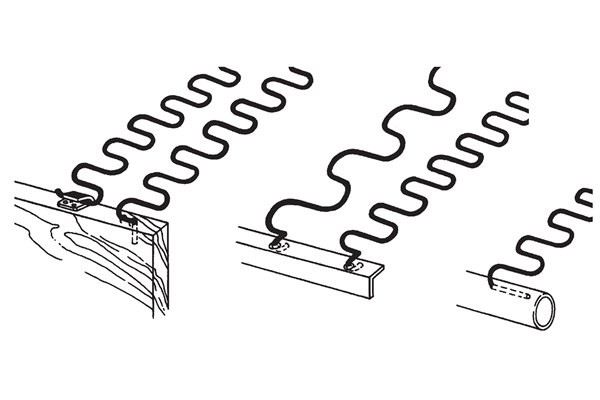

The tension spring is replaced by today’s commonly used S (No-Sag) spring, thanks to its invention by American company Leggett&Platt

Leggett&Platt has become not only a major supplier for furniture, automobile and aircraft factories, but is also represented in the textile, manufacturing and construction industries.

![]()

Thanks to the German industrial revolution and the development of the chemical industry, today’s popular Polyurethane foam mattresses appeared

1937

1968

Charlie Hall’s waterbed is an instant success. In 1987, one out of five mattresses purchased in America were waterbeds.

![]()

NASA’s 1966 development takes over the furniture industry and thanks to the Swedish brand Tempur, memory foam mattresses and pillows appeared.

Today, Tempur Sealy is present in 100 countries around the world and is the world’s largest mattress manufacturer. Its name is familiar to everyone and fused with the concept of memory foam.

1991

1993

Special cell structure air mattresses are designed to replace water beds because waterbeds:

● are heavy

● fragile

● need to be heated

● wallow

● its hardness is not adjustable

Individually customizable mattresses started with air beds.

The age of adjustable, customizable mattresses

2004

A Japanese patent implemented an adjustable hardness mattress with an electric pump used to stretch out the spring core of the mattress.

In the early 2000s, a fully customizable mattress created the 2nd generation of mattresses.

In America, one of today’s best-known hardness adjustment technologies (available from $2,000) is released. It uses an electrical system to adjust the hardness of the mattress through an integrated airbag layer.

2006

2006

Reverie mattress manufacturers introduce DreamCell technology (family mattress available from $2,700), allowing the user to change the mattress hardness by replacing the pillows in the mattress core.

The American manufacturer Reverie is the second largest manufacturer of adjustable mattresses, producing the first only manually adjustable hardness mattresses without the use of manual electricity.

There is no better indication for the demand for adjustable hardness mattresses than the leading American manufacturer of adjustable mattresses, Sleep Number Corp., who sold over 13,000,000 beds and mattresses by 2020, and made $1.86 billion in sales in the US in 2020.

Thanks to the adjustable mattresses and the quality service developed around them, Sleep Number was awarded the EY Entrepreneur Of The Year Award in 2019, which is one of the biggest international awards for companies striving for innovation improvements that improve human life

EFC, a Hungarian comfort technology, makes the luxury of hardness adjustment available to EVERYONE. EFC allows for the integration of adjustable hardness in any seating or reclining surface that is already in production without the use of external energy, compressors or other technologies, at any time, with a single gesture, with a negligible change in cost of production.

2021

We believe that EFC technology is causing a change in the market similar to the introduction of the Marshall bag spring in 1902.

EFC technology also enables everyone to freely adjust the hardness and softness of modern seating and reclining surfaces.

The last 20 years have shown that truly successful innovations offer a solution to people’s individual needs for comfort, functionality and design. The change can come much, much faster now than in 1902.

Begin a dialogue

with us!

Start the process of EFC comfort technology integration

with us!

We will guide you step by step through the possibilities of adopting our technology, helping you to make an ideal decision on the application of the technology with all the necessary information.

The aim of the integration process is to effectively identify the benefits and potential challenges associated with the use of the new comfort technology. Of course, starting a dialogue does not in itself entail commitment.

I am a furniture or mattress manufacturer, I want to ask for more information and register. I want to use EFC technology.

What additional benefits can the use of this technology bring as a furniture manufacturer?

A detailed presentation of EFC in practice

Historical presentation

The past will reveal a great future